Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

Build a stronger, more competitive product with our value.

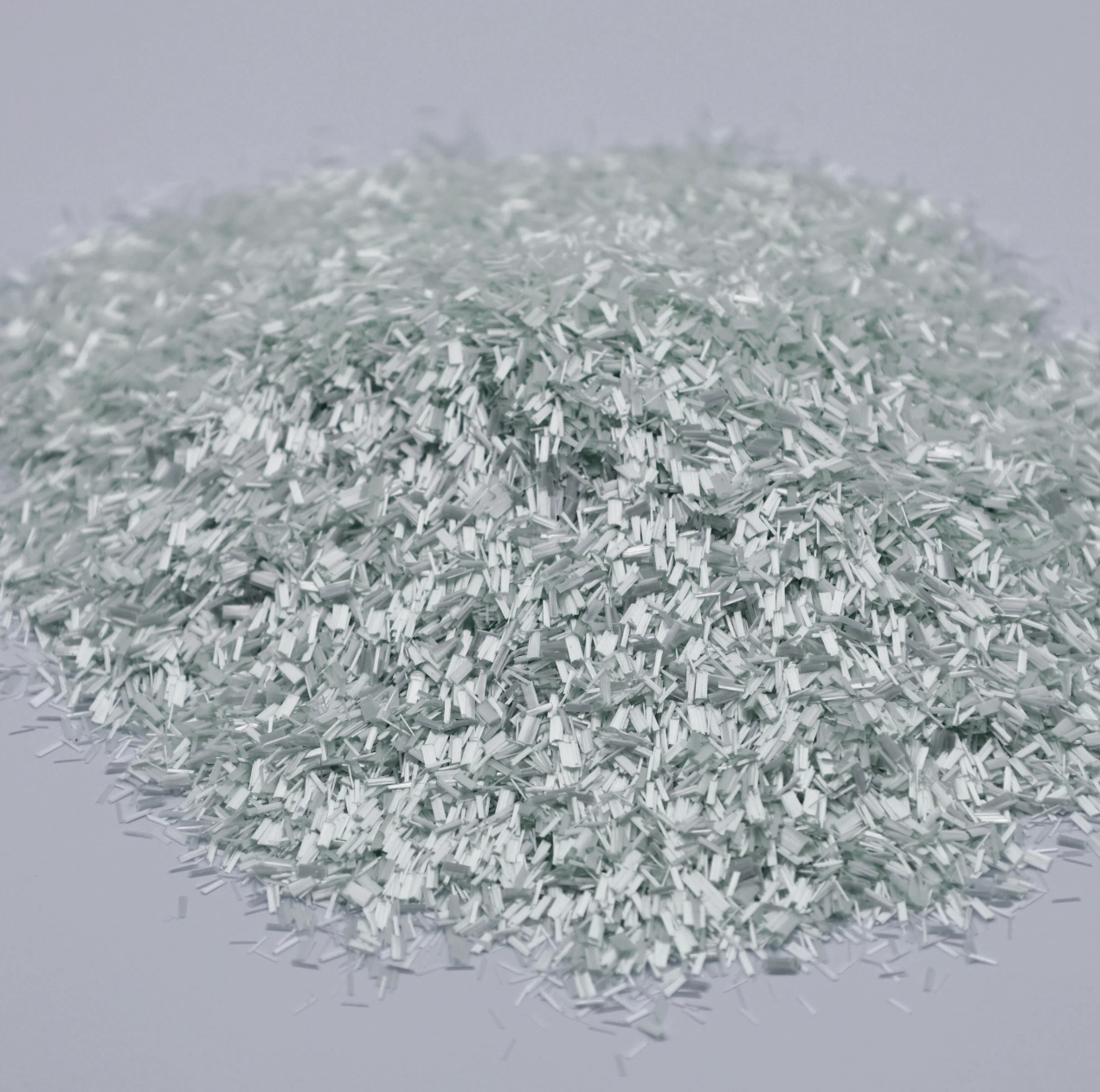

Outstanding strength to weight ratio is a key technical edge that differentiates premium chopped strand mat from others. It is a mat that provides impressive structural strength but is not bulky. This differs from other traditional materials that are heavier and more bulky. Chopped strand mat is ideal for weight-critical applications in transportation, building materials, and aerospace where structural strength needs to be preserved. This characteristic is also a key factor in end product performance, and because of this, energy efficiency has to be considered. Raising efficiency is also a growing concern in the present market for businesses. More competitiveness is given to products and lower weights are achieved leading to more savings in materials. Performance and sustainability are achieved without compromising on durability.

Quality products sold on the market must have an even quality of uniform fiber distribution present in balanced amounts in mats. Without uniform fiber quality distribution, an inferior product with a clumping of fibers, a product that is evenly weak with a poor quality unacceptable product performance, is a product that is consistent lead a a higher product failure. More premium alternatives, on the other hand, have no weak points in the even quality of fiber distribution present. This consistency provides an ample guarantee that all ends of the mats environment and defect free construction will contribute to the positive ends support in the positive construction usable finish. In lack of the construction usable ends the positive environmental impact value is defect free. This positive impact provides an increased premium value products reputation and service the loyal customers with satisfaction. This translates and higher end products and reduces reliance on inefficient over production of the mats, and end products. All of which improve and build a more positive client reputation in their over all business.

Superior quality chopped strand mat is compatible with many kinds of resins; this rare technical aspect has important economic implications. It captures resins quickly and uniformly allowing better fiber-resin bonds and producing better composites. This compatibility makes the manufacturing process easier, streamlining processing time and alleviating problems associated with poor adhesion or incomplete curing. Unlike flimsy, low-quality mats that tend to require niche resins and additional processing, premium mats can be used as is, directly within existing production lines. This saves companies time and money as no equipment changes or costly material substitutions are necessary. This quality makes premium mats a go to solution for makers in all industries from components in the chemical field to parts in the electrical and electronic fields.

The big difference between low and high quality chopped strand mats is how well they work at moisture and corrosion resistance. In extreme conditions like marine applications and outdoor infrastructure, chemical processing, and facilities, low grade mats can quickly evolve into product failure. However, premium quality mats resist corrosion chemical, moisture, and weather factors, resulting in a great length of service for the composite products they reinforce. More than enough maintenance, long product life, and reliability is what durability means for the end users. More warranty claims, high customer trust, and for the businesses, a pretty decent impact on the bottom line.

Among all product categories of fiberglass mat, a real premium product is one without debate cost-effective product, and this is because of the cost benefits discussed next. Sure, premium products may have a higher upfront cost than a mat of a poorer quality, however, on a whole, the benefits mitigated over a lifetime, of each premium mat, outweigh the cost differential. The quality of the premium mats reduces quality wastage, and to add, it reduces the downtime of production as a result of processing issues, and it reduces the overall cost of replacements. Plus, because of the quality of the mats themselves, they will likely increase the quality of the end products, which, from the outset, justifiy higher selling prices of businesses, enabling greater profits. Lastly, and of utmost importance is the premiums offered on mats of equal quality on the market, a premium chopped strand mat by all means is affordable and accessible, without sacrificing quality.

Chopped strand mats offer one of the most adaptable products used in multiple industries including infrastructure, construction, transportation, sports, leisure, and more. It offers excellent performance and fulfills a variety of manufacturing processes. It has the exceptional engineering flexibility to be molded into a variety of industrial applications, whether used to form intricate shape structures, promote consolidation in large structures, and augment several other production processes. Its engineering flexibility permits industrial players to avoid the hassle of sourcing a multitude of other materials. From aerospace to energy saving, the adaptable performance of premium chopped strand mats in diversified sectors makes it one of the most reliable and preferred materials.